Home > Equipment > Thermoformers > Compact Thermoformers

Compact Thermoformers

Thermoforming machines are great for high-volume output used for a wide variety of food & medical products. The thermoforming process is done by feeding rollstock film into the automated horizontal form-fill-and-seal (HFFS) equipment. Flexible or semi-rigid film is then heated and formed into the packaging moulds, such as trays or cups.

These thermoformers are 100% stainless steel, so they are easy to clean and maintain. With programmable settings, these machines can flexibly be set to fit your production needs.

Home > Equipment > Thermoformers > Compact Thermoformers

Compact Thermoformers

Thermoforming machines are great for high-volume output used for a wide variety of food & medical products. The thermoforming process is done by feeding rollstock film into the automated horizontal form-fill-and-seal (HFFS) equipment. Flexible or semi-rigid film is then heated and formed into the packaging moulds, such as trays or cups.

These thermoformers are 100% stainless steel, so they are easy to clean and maintain. With programmable settings, these machines can flexibly be set to fit your production needs.

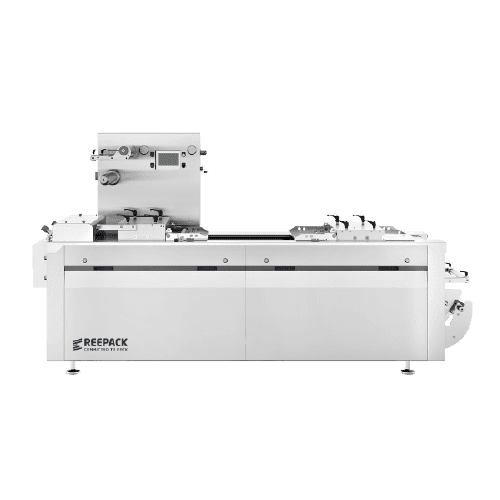

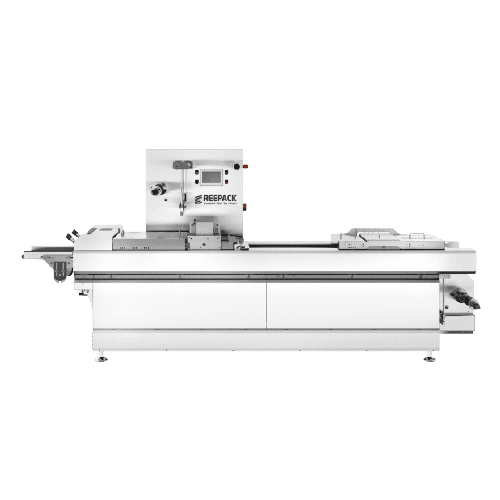

Compact Thermoformer

Models

Reepack ReeForm E05

Reepack ReeForm E05

Reepack ReeForm E10

Reepack ReeForm E10

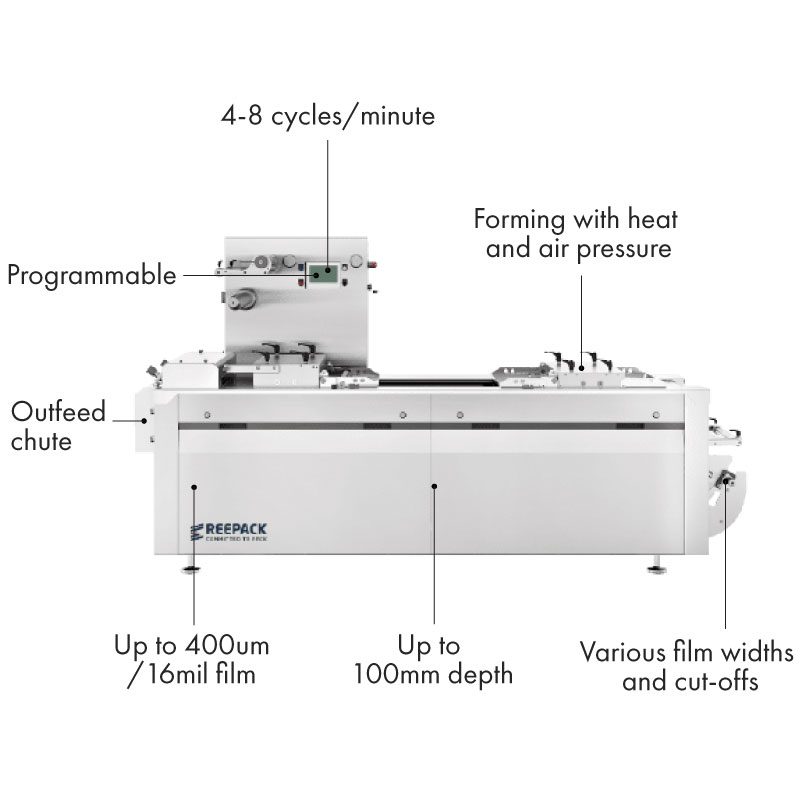

Compact Thermoformer

Features

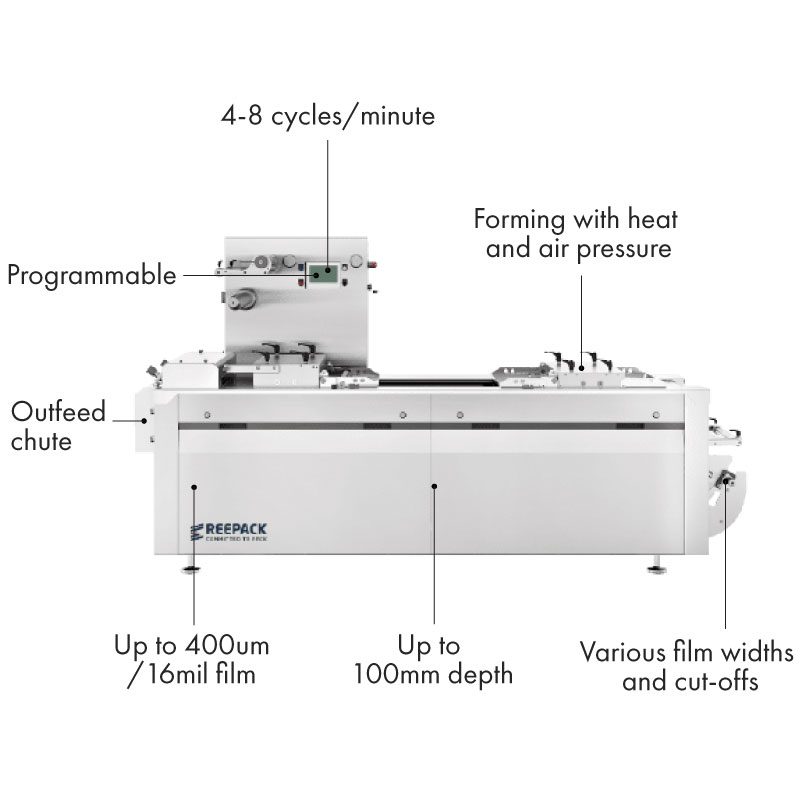

4-8 cycles / minute

Forming with heat and air pressure

Outfeed chute

Various film widths and cut-offs

Up to 400um / 16mil film

Programmable

Up to 100mm depth

Related

Markets

Cheese & Dairy

Mix and match your cheese and dairy packaging from pouches to films to shrink bags for any application.

Confectionery

Packaging for baked goods, chocolates, and candies is critical for keeping your products fresh and intact.

Frozen Foods

With frozen foods, increasing shelf life and decreasing freezer burn is top priority, though easy sealing and opening packaging doesn’t hurt.

Jerky

When choosing your packaging for jerky and cured meat products, the freshness and shelf-life is top of mind.

Meat & Seafood

Looking to up your meat and seafood packaging game? We have moisture and oxygen barrier capabilities that will do just that.

Pet Food

When it comes to pet food packaging, no compromises to quality, convenience, or printing should be made.

Produce

Keep your fruits and vegetables shelf-quality with perforated film or modified atmosphere packaging.

Snacks

Whatever the snack you've perfected, we want to make sure it gets to your customers exactly how you intend.

Have a project in mind?

Get in touch today for a custom quote.