Modified atmosphere packaging.

Have you ever found yourself wondering, “What’s the deal with all the air in these chip bags?” While not all products have quite as much air as potato chips, a lot of products also add modified air into their bags. Are they letting us pay more for less product, or is there another reason for the added space?

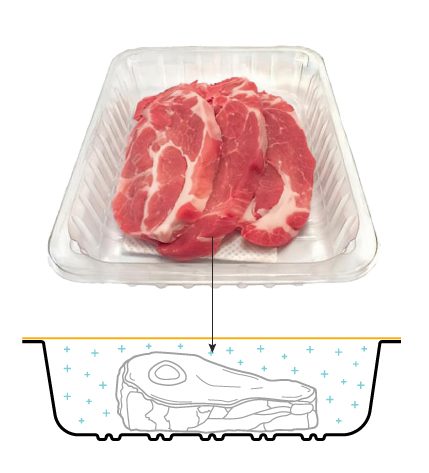

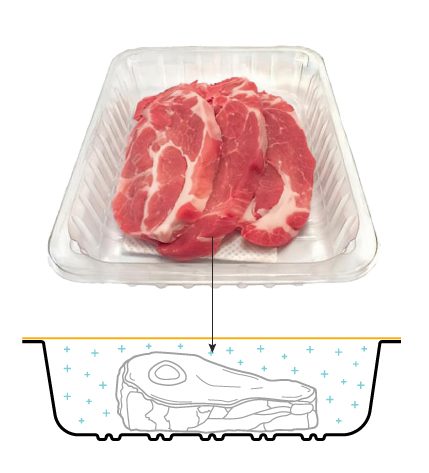

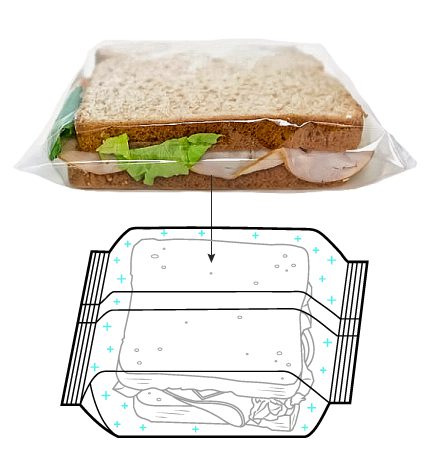

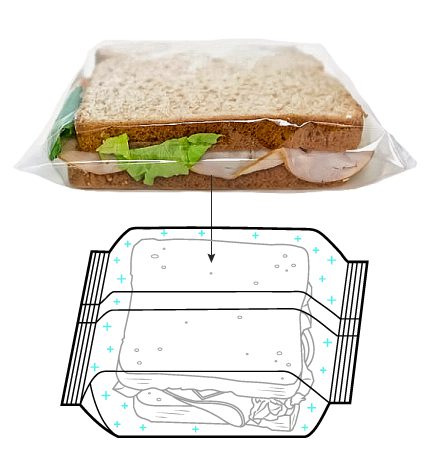

Modified atmosphere packaging (MAP) is a packaging technique where the air in the food package is altered. This is normally done by replacing the air inside the package with a gas mixture that contains lower levels of oxygen and higher levels of carbon dioxide and nitrogen. The use of MAP is becoming increasingly common in the food industry for many reasons, but how do you know if your product should have it?

Why do food producers use modified atmosphere packaging?

Extend the shelf life of the product

Oxygen promotes the growth of microorganisms, which is one of the main causes of spoilage in food products. By replacing the oxygen in the packaging with nitrogen and carbon dioxide, the growth of these microorganisms can be slowed down.

Improve food quality

Oxygen can cause oxidative damage to the chemicals in your food product, which can cause spoilage, discoloration, and it can even change the flavours and aromas of the food.

Protect from moisture

Some foods can become stale or soggy if exposed to too much moisture. By using a gas mixture in the packaging, the moisture levels can be controlled, which helps to preserve the freshness and texture of the product.

Protect the product from external factors

Certain foods, like potato chips, have modified air in the bag to prevent the product from being crushed alongside the reasons listed above. This reduces waste and improves product appearance by keeping your product in good condition through rigorous shipping and handling processes.

How do I know if my food product needs MAP?

The answer depends on a variety of things, including the type of product, its sensitivity to oxygen, moisture, and the desired shelf life. A consultation with a food scientist or food lab can help to determine the best solution for your specific product. Along with consultation, shelf-life testing can also be used to find the right gas mixture to keep your product fresh for longer.

What needs to be adjusted in my packaging to optimize shelf life?

1. Packaging structure.

Different plastic layers will have different levels of oxygen permeability, meaning some types of plastics will let in more air than others. Often, higher barrier structures are used to prevent air exchange, keeping air out of the packaging while keeping the gas mixture in.

2. Gas mixture.

The specific gas mixture, for example, the ratios of nitrogen and carbon dioxide, can be optimized to your application. Consulting a food lab or a food scientist is the best way to determine what atmosphere is best for your product and shelf-life targets.

Common types of gases used for modified atmosphere?

Carbon dioxide: has antibacterial properties that prevents common microorganisms from growing.

Nitrogen: a non-reactive gas that displaces reactive gasses like oxygen that can negatively affect the product. It can also be used to balance pressure in the package.

Oxygen: can be used for certain products like seafood to prevent discoloration and prevents the growth of microorganisms that can’t grow in the presence of oxygen.

What packaging machines have MAP options?

To wrap up, the use of nitrogen or gas mixtures in food packaging is a popular and effective way to extend the shelf life of the product, protect it from external factors, and improve its quality.

Consultation with a food scientist can help to determine the best solution for your specific product and can lead to higher profitability and consumer satisfaction.

Share this post

Have a project in mind?

Get in touch today for a custom quote.