Home > Equipment > High-Production Automatic Tray Sealers > Reepack ReeMaster 1000

Reepack

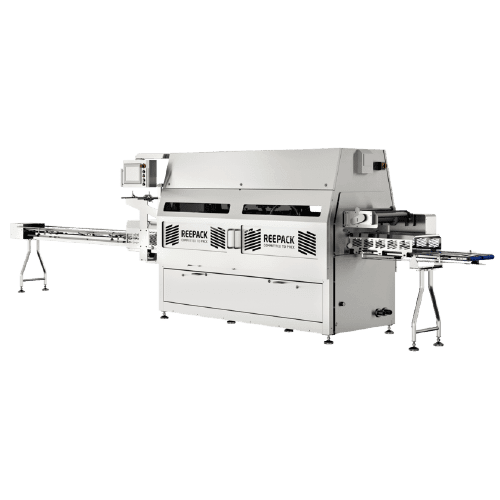

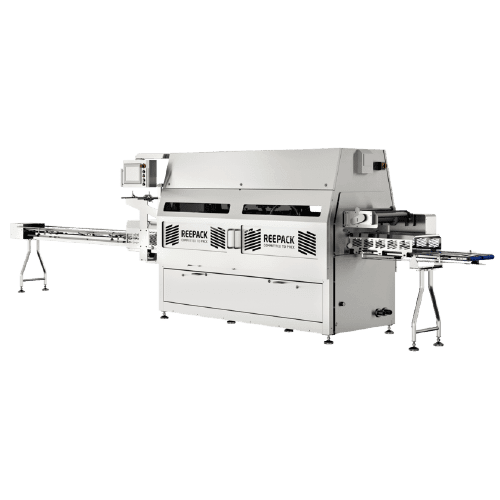

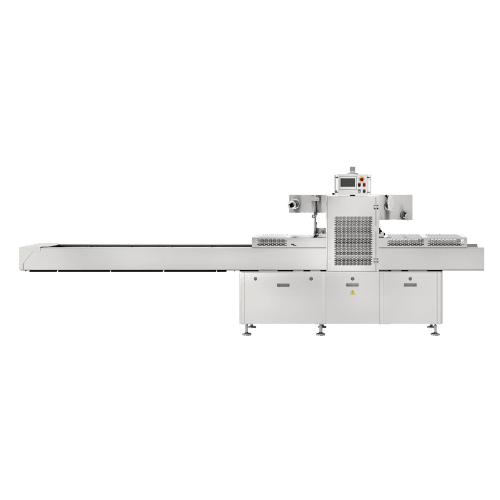

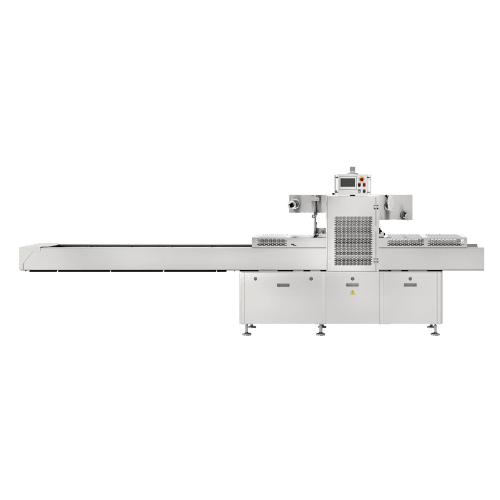

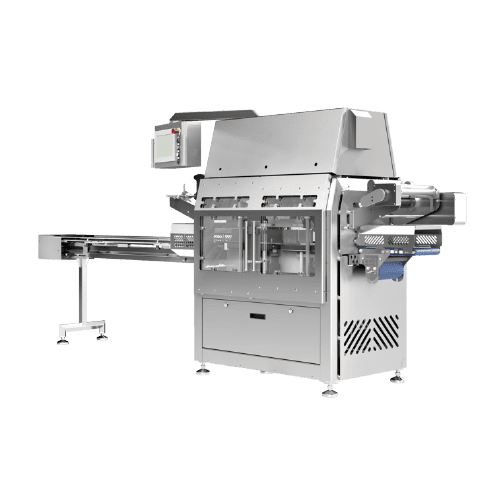

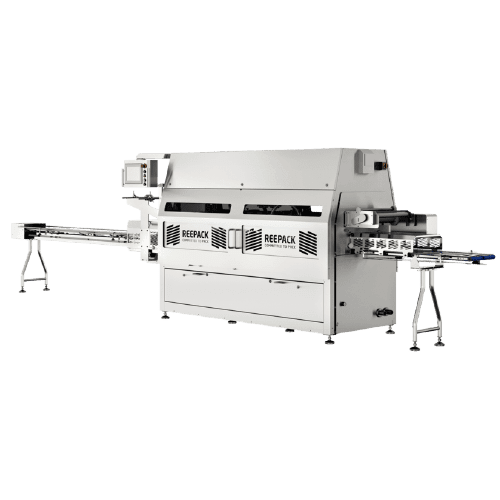

ReeMaster 1000

The ReeMaster 1000 is the widest unit to produce large batches of products with optimal efficiency, or those large products that don’t fit in any other unit. This unit is built to be integrated into a high-production food processing line.

These tray sealers support one or two track inline trays that are configured with patented pick and place robotics to pack up to 6 trays across two lines with incredible accuracy. Available for MAP and vacuum skin packages with preformed trays of almost any size, quality, or shape.

The ReeMaster 1000 is the widest unit to produce large batches of products with optimal efficiency, or those large products that don’t fit in any other unit. This unit is built to be integrated into a high-production food processing line.

These tray sealers support one or two track inline trays that are configured with patented pick and place robotics to pack up to 6 trays across two lines with incredible accuracy. Available for MAP and vacuum skin packages with preformed trays of almost any size, quality, or shape.

Reepack ReeMaster 1000

Specifications

Max dimensions: 8300 x 1250 x 2050 mm

Control panel: Touchscreen

Infeed conveyor length: 2000 – 5000 mm

Vacuum Pump: Busch 200 m3/h

Length free loading area: 1300 – 4300 mm

Electrical supply: 3Ph / 230V / 60Hz

No. of trays to load: 3-25

Electrical power: 30kW

Height free loading area: 920 – 980

Compressed Air: S = 0, MAP = 0

Machine main movements: Servo-drivers

Stainless steel construction

Microprocessor Control: PLC-Siemens

360° access to all machine components and tooling

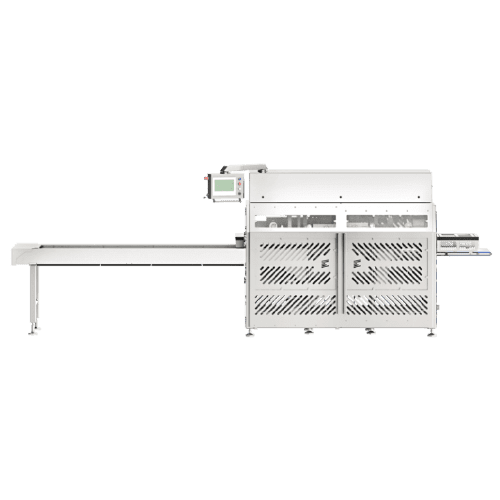

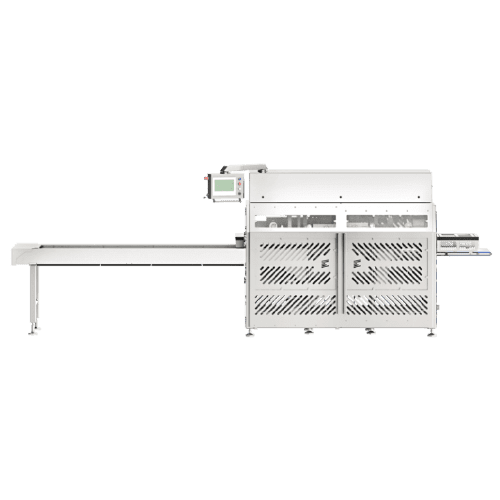

Reepack ReeMaster 1000

Options and Add-ons

Photocell for printed film

Upgraded Busch pump

Printing and labelling units

Tray de-nester device

Vibrator unit

Combining conveyor belt

Snap on lid device

Multi-load dispencer

Metering unit device

Inkjet coder

Reepack ReeMaster 1000

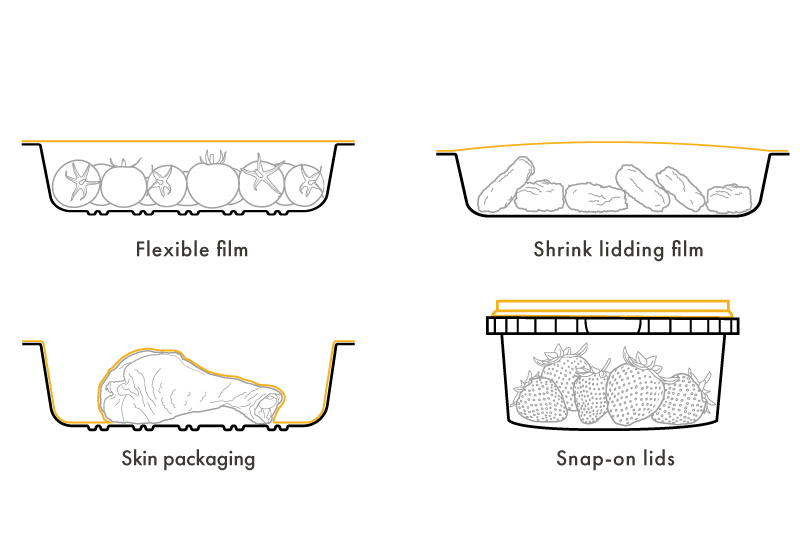

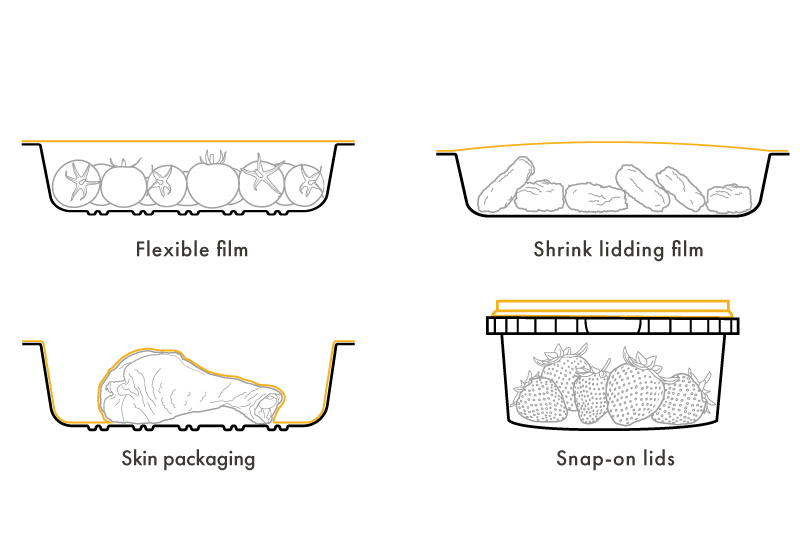

Envision your packaging product.

When getting product into retail and wholesale applications, one of the first thoughts that comes up is how the finished product will present on the shelf. Packaging has a large impact on your brand, which is why it’s important to have a high-quality packaged product with the right look and feel to help you stand out on the shelf.

With a variety of tray sealers with different capabilities, our packaging consultants can help you find the right fit for any of these packaging types and applications.

Packaging options

Trays & Closures

Types of Trays

• Microwavable

• Dual ovenable

• High/medium/low barrier

• Skin boards

• Deli containers

• Aluminum

• Pressed paper

• Pulp

Types of closures

• Flexible film

• Skin packaging

• Shrink lidding film

• Snap-on lids

Packaging options

Film Features

Microwaveable

Oven safe

Re-sealable

Anti-fog

Micro perforation

Packaging options

Sealing & Atmosphere Applications

Ambient packaging

An airtight straight seal with no vacuum or altered atmosphere applied. This is the simplest form of seal and often used with frozen products, or fresh products with micro-perforations and other breathable films.

Skin pack (VSP)

Air is removed from the flexible packaging to protect the product from oxygen, extending the shelf life. This is often used with a tightly sealed package when the product has more rigidity

Modified atmosphere packaging (MAP)

In this process, air is vacuumed out and replaced with carbon dioxide, nitrogen, or a gas mixture. This is used to extend the shelf life and keep products fresh, especially with delicate or perishable foods

Pro-skin

Pro skin is similar to vacuum skin packaging, but specialized equipment is required when the product

protrudes over the lip of the tray.

Cardboard pro-skin

Cardboard skin packaging is an innovative, eco-friendly option that uses a paper board instead of plastic in the pro-skin packaging process.

Other Automatic Tray Sealer

Models

Reepack ReeMatic 150

Reepack ReeMatic 150

Reepack ReeMatic 250

Reepack ReeMatic 250

Reepack ReeMaster 400

Reepack ReeMaster 400

Reepack ReeMaster 400 M

Reepack ReeMaster 400 M

Reepack ReeMaster 600

Reepack ReeMaster 600