Home > Equipment > Belted Vacuum Sealers > Reepack BT-1000

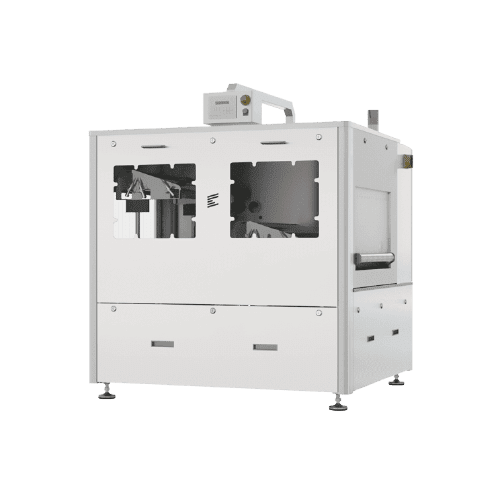

Reepack BT-1000

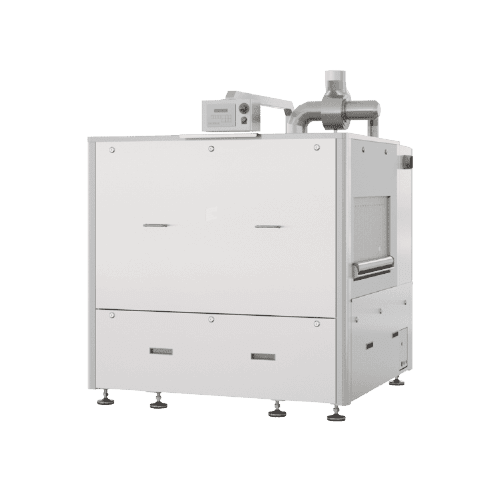

Automate your business with a high-quality belted chamber vacuum sealer. The conveyor belt allows you to load your product at one end, where it is then advanced into the vacuum cycle and then sent to the unloading portion of the machine for unload. These machines can also be used in conjunction with belted shrinking and drying tunnels for further automation.

The pressure-controlled vacuum ensures evacuation and gas flushing processes are consistent and airtight every time. The Reepack BT-1000 is made from stainless steel, features a Busch 305m3/h (12 hp) pump, (2) 1000mm seal bars, and a digital control panel that can store up to 10 different programs.

Automate your business with a high-quality belted chamber vacuum sealer. The conveyor belt allows you to load your product at one end, where it is then advanced into the vacuum cycle and then sent to the unloading portion of the machine for unload. These machines can also be used in conjunction with belted shrinking and drying tunnels for further automation.

The pressure-controlled vacuum ensures evacuation and gas flushing processes are consistent and airtight every time. The Reepack BT-1000 is made from stainless steel, features a Busch 305m3/h (12 hp) pump, (2) 1000mm seal bars, and a digital control panel that can store up to 10 different programs.

Reepack BT-1000

Specifications

Seal Bar Length: 2 x 1000mm

Pneumatic moving guides at the infeed

Distance between the bars: 600mm

Infeed conveyor belt with electronically adjustable speed

Chamber Height: 250 or 300mm

Stainless steel construction

Busch 305m3/h (12.0 hp) vacuum pump

Stainless steel lid

Micro PLC control with 10 storable programs

Automatic lid closure

Bi-active sealing

Electricity: 208V / 3 Ph / 60 Hz

Independent control of seal bars

Machine Dimensions: 2935mm x 1300mm x 1950mm

Pre-sealing phase to remove fats or fluids from the area

Machine Weight: 2,050 lbs

Pneumatic movement of the chamber with a safety hydraulic brake

Reepack BT-1000

Options and Add-ons

Vacuum booster

Pump upgrade

Ribbed conveyor belt

Pneumatic scrap cutters

Bag holding device

Automatic shrink tunnel

Drying tunnel

Other Belted Vacuum Sealer

Models & Related Equipment

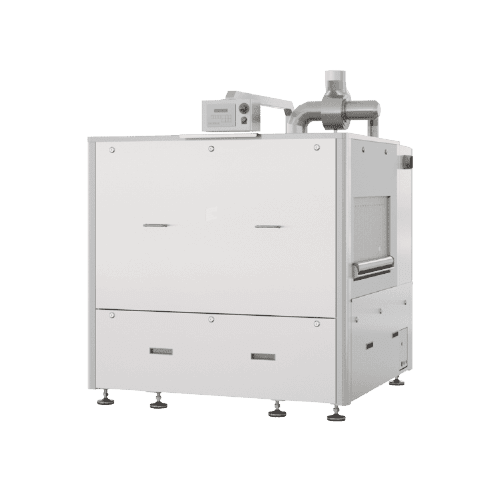

Reepack BT-1350

Reepack BT-1350

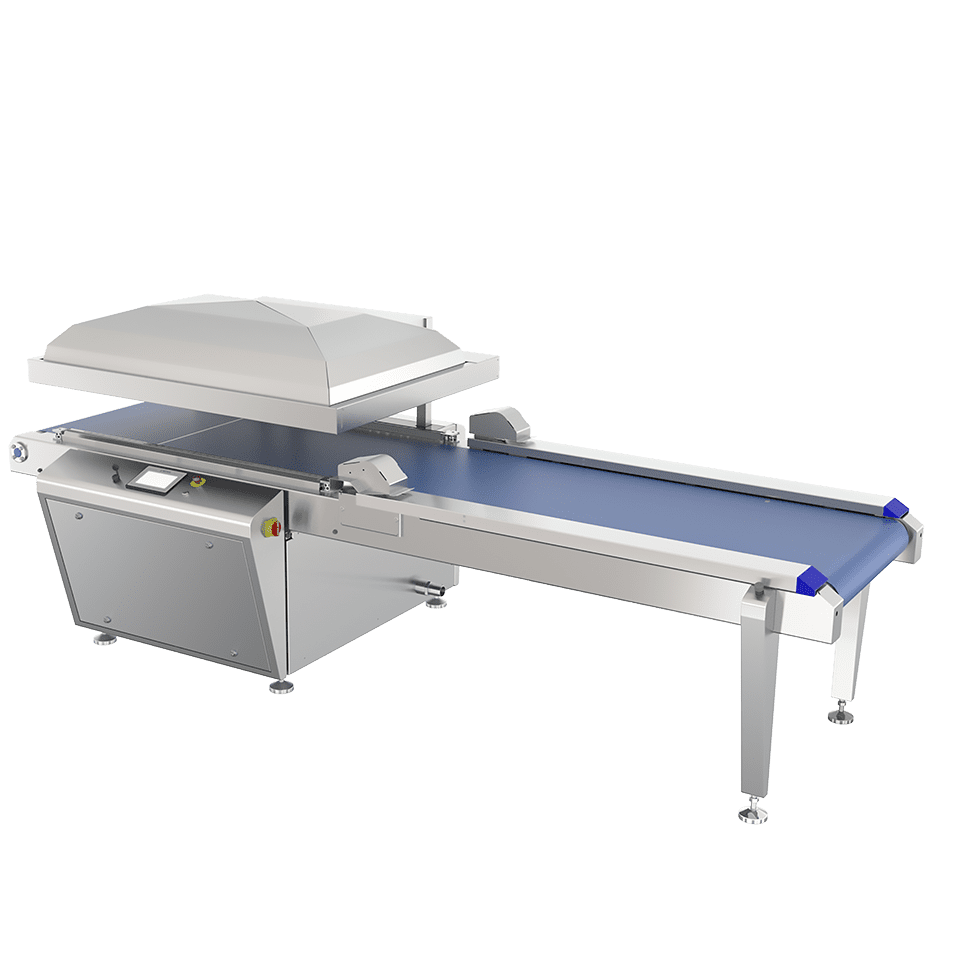

Reepack ST100 Shrink Tunnel

Reepack ST100 Shrink Tunnel