Home > Equipment > Long Dwell Flow Wrappers > Reepack ReeFlow 200 BW

Reepack

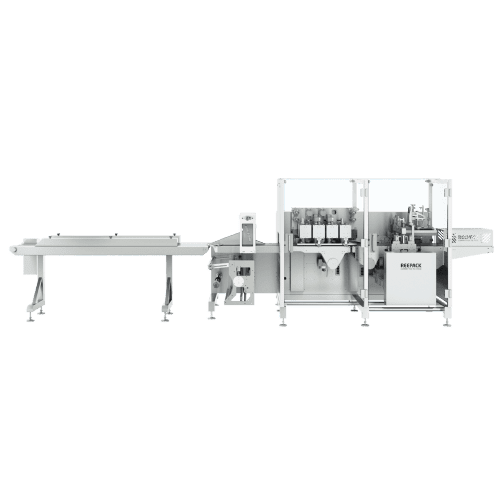

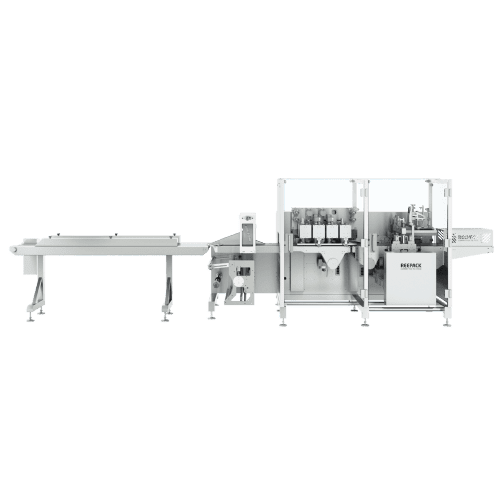

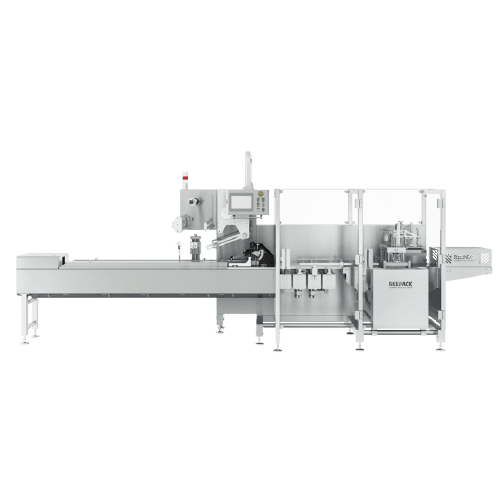

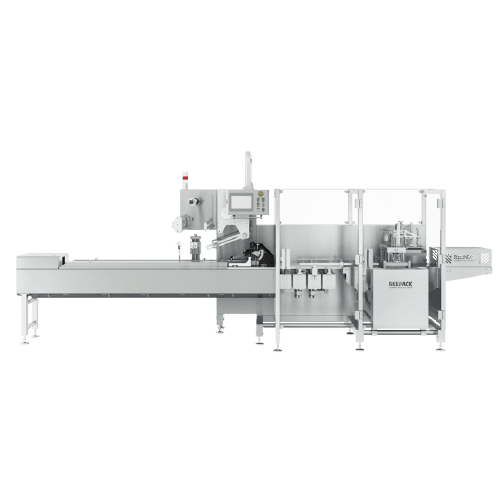

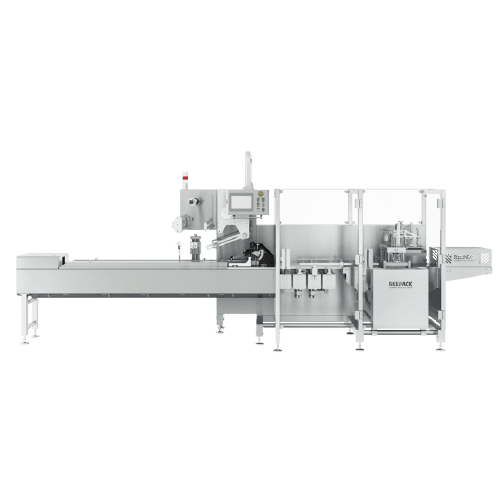

ReeFlow 200 BW

The ReeFlow 200 series are fully electric Servo driven flow wrappers for high quality, precise, and high production capabilities. Unlike standard flow wrappers, Long-Dwell series allows for longer contact with the film for thicker or specialized films for an airtight seal without melting the plastic.

Long-Dwell 350mm jaws have a production speed of 120-200 ppm with varying jaws. With a driven reel shaft for film from 800mm and automatic film tensioning which allows you to run even the thinnest of films, you can be sure that these machines will efficiently process your products.

The ReeFlow 200 series are fully electric Servo driven flow wrappers for high quality, precise, and high production capabilities. Unlike standard flow wrappers, Long-Dwell series allows for longer contact with the film for thicker or specialized films for an airtight seal without melting the plastic.

Long-Dwell 350mm jaws have a production speed of 120-200 ppm with varying jaws. With a driven reel shaft for film from 800mm and automatic film tensioning which allows you to run even the thinnest of films, you can be sure that these machines will efficiently process your products.

Reepack ReeFlow 200 BW

Specifications

Machine dimensions: 5400x1400x1800mm

Infeed conveyor: Belted infeed

Max film speed: 60m/min

Max product height: 160/180mm

Long dwell jaw size: 350mm

Bag width: 250/400mm

Max film width: 800mm

10” Touch screen panel

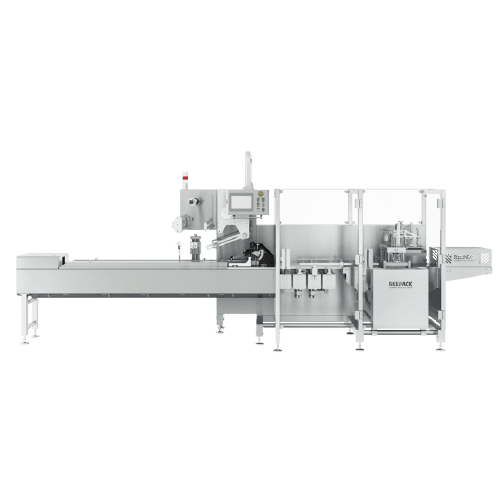

Reepack ReeFlow 200 BW

Options and Add-ons

Fixed/ Adjustable Folding Boxes

Flat belt infeed/multibelt feeder

Misplaced product detection

Gas flush, mix and analyzer

Automatic label applicator

Printers for date/lot coding

Photocell registration

No product - no bag

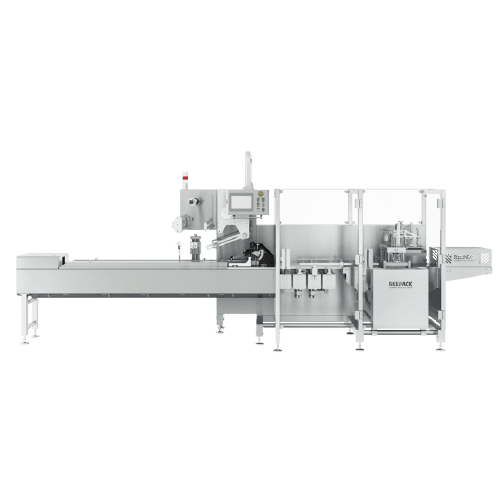

Reepack ReeFlow 200 BW

Envision your packaging product.

When getting product into retail and wholesale applications, one of the first thoughts that comes up is how the finished product will present on the shelf.

Packaging has a large impact on your brand, which is why it’s important to have a high-quality packaged product with the right look and feel to help you stand out on the shelf.

With a variety of flow wrappers with different capabilities, our packaging consultants can help you find the right fit for any of these packaging types and applications.

Packaging options

Film

Types of Films

• Hot seal

• Cold seal

• High barrier

• Monostructure

• Shrink

Film Features

• Microwaveable

• Oven safe

• Re-sealable window

• Anti-fog

• Micro-perforated

Packaging options

Folding

Back fin

Gusseted back fin

Packaging options

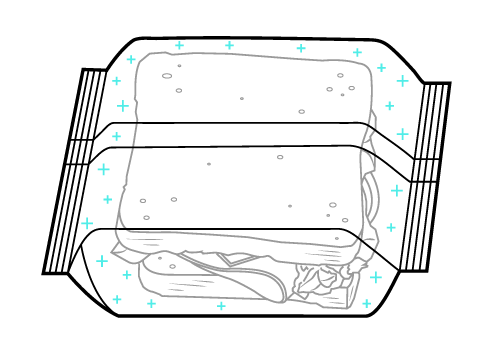

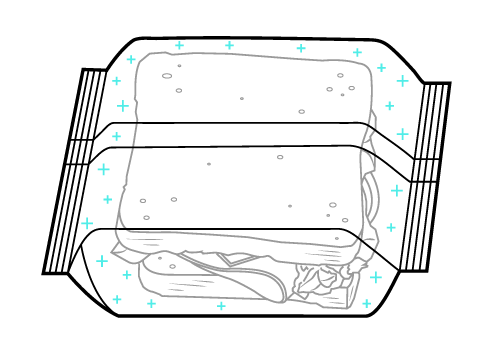

Sealing & Atmosphere Applications

Ambient packaging

An airtight straight seal with no vacuum or altered atmosphere applied. This is the simplest form of seal and often used with frozen products, or fresh products with micro-perforations and other breathable films.

Modified atmosphere packaging (MAP)

In this process, air is vacuumed out and replaced with carbon dioxide, nitrogen, or a gas mixture. This is used to extend the shelf life and keep products fresh, especially with delicate or perishable foods

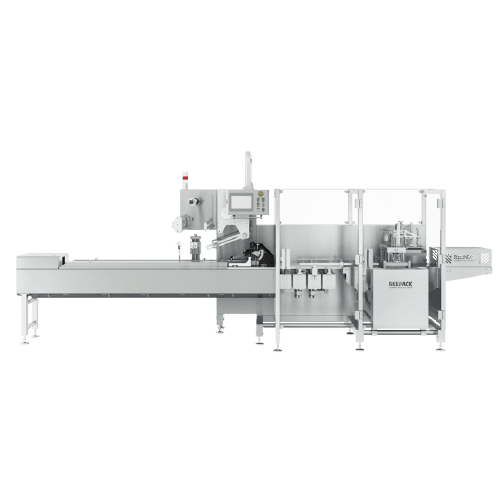

Other Long Dwell Flow Wrapper

Models

Reepack

ReeFlow 200 T

Reepack

ReeFlow 200 T

Reepack

ReeFlow 200 TW

Reepack

ReeFlow 200 TW