Home > Equipment > Full Size Thermoformers > Reepack ReeForm E30

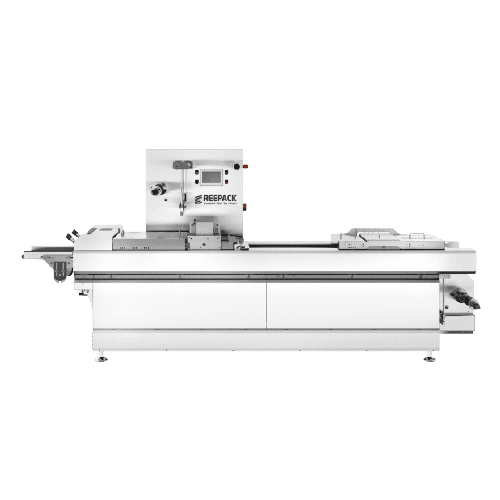

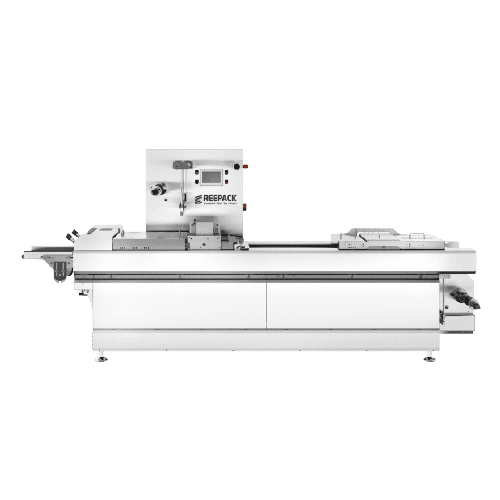

Reepack ReeForm E30

A compact thermoforming machine for small and medium production output. Manufactured with a stainless-steel frame for better sanitation in full washdown environments. A user-friendly control panel provides users with access to straight-forward setting and recording of various programs, allowing for maximum flexibility with different packaging formats and products.

The ReeForm E30 can process flexible and semi-rigid films up to 500 microns thick with a film width of up to 420mm. Maximum forming depth of 120mm and maximum cut-off up to 300mm. The processing stations are electric in motion, allowing for good energy savings as well as minimum maintenance. Air pressure is only required for the forming and sealing stations.

A compact thermoforming machine for small and medium production output. Manufactured with a stainless-steel frame for better sanitation in full washdown environments. A user-friendly control panel provides users with access to straight-forward setting and recording of various programs, allowing for maximum flexibility with different packaging formats and products.

The ReeForm E30 can process flexible and semi-rigid films up to 500 microns thick with a film width of up to 420mm. Maximum forming depth of 120mm and maximum cut-off up to 300mm. The processing stations are electric in motion, allowing for good energy savings as well as minimum maintenance. Air pressure is only required for the forming and sealing stations.

Reepack ReeForm E30

Specifications

Machine Length: 4220mm

Free Positions: 5 – 5 – 4 – 4

Machine Height: 1700mm

Thermoforming Depth: Max. 120mm

Machine Width: Max. 1070mm

Maximum Film Thickness: 500um / 20mil

Bottom Film: 320 – 360 – 420mm

Machine Cycles: 5-10 cycles / minute

Cut-off Length: 200 – 240 – 270 – 300mm

Forming with heat, air pressure, and vacuum

Product Loading Area: 1000 – 1200 – 1080 – 1200mm

Outfeed chute

Reepack ReeForm E30

Options and Add-ons

Modified atmosphere packaging

Skin packaging

Easy peel corners

Bottom and/or top film print registration

Hinged upper chamber for quick format change

Printing unit for date/lot coding

Rewind system with motorized rolls

Upgraded vacuum pump outside machine frame

Reepack ReeForm E30

Envision your packaging product.

When getting product into retail and wholesale applications, one of the first thoughts that comes up is how the finished product will present on the shelf. Packaging has a large impact on your brand, which is why it’s important to have a high-quality packaged product with the right look and feel to help you stand out on the shelf.

With a variety of thermoformers with different capabilities, our packaging consultants can help you find the right fit for any of these packaging types and applications. Thermoformers have a wide range of packaging styles across different units to suit your product.

Packaging options

Film

Types of Films

• Flexible

• Semi-rigid

• Monostructure

• Skin

Film Features

• Microwaveable

• Oven safe

• Re-sealable

• Anti-fog

• Micro-perforated

• Easy peel

• Lock seal

Packaging options

Forming

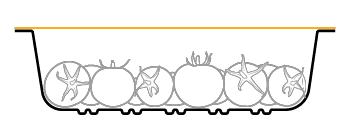

Flexible forming

Semi-rigid forming

Packaging options

Sealing & Atmosphere Applications

Ambient packaging

An airtight straight seal with no vacuum or altered atmosphere applied. This is the simplest form of seal and often used with frozen products, or fresh products with micro-perforations and other breathable films.

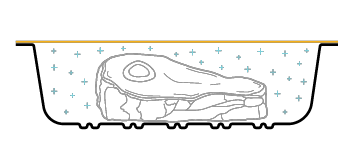

Vacuum packaging

Air is removed from the flexible packaging to protect the product from oxygen, extending the shelf life. This is often used with a tightly sealed package when the product has more rigidity.

Modified atmosphere packaging (MAP)

In this process, air is vacuumed out and replaced with carbon dioxide, nitrogen, or a gas mixture. This is used to extend the shelf life and keep products fresh, especially with delicate or perishable foods

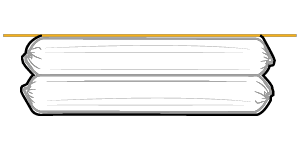

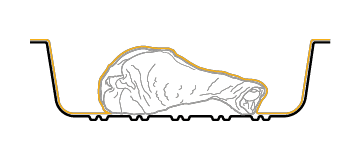

Vacuum skin pack (VSP)

Skin packaging uses a specialized film which seals to a rigid or semi-rigid bottom film. When heated, the film will form around the product and act like a second skin for a professional appearance.

Full Size Thermoformer

Models